Welded steel pipes are divided into:

Electric Resistance Welded Pipe(ERW),Spiral Steel Pipe(SSAW),Longitudinal Submerged Arc Welded Pipe(LSAW)

Size:

①ERW Steel Pipe:

OD: 21.3mm ~ 660mm;WT: 1mm ~ 17.5mm; LENGTH: 0.5mtr ~ 22mtr

②LSAW Steel Pipe:

OD: 406mm ~ 1422 mm;WT: 6.4mm ~ 44.5mm;LENGTH: 5mtr ~ 12mtr

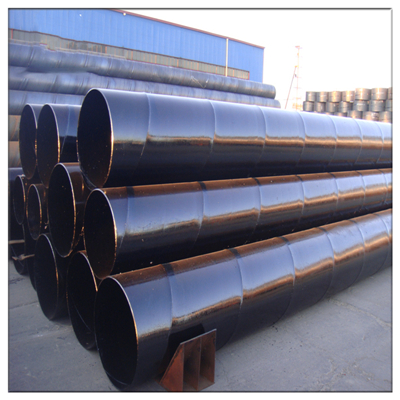

③SSAW Steel Pipe:

OD:219.1mm ~ 3500mm; WT: 6mm ~ 25mm (Up to 1'');LENGTH: 6mtr ~ 18mtr, SRL, DRL

Standard & Grade:

ASTM A53, Grade A/B/C,API 5L,PSL1,PSL2,GR.B/X42-X80,ASTM A795,ASTM A135,ASTM A252,GR.1/2/3,AWWA C200

▇ ▍ Description

Welded steel pipe is created using a flat steel plates or steel strips, and its manufacturing process creates seams in its body. Specifically, when welded steel pipes are manufactured, a steel plate or strip is bent and subsequently welded into either a circular, traditional pipe shape or a square shape.LSAW pipe, SSAW pipe and ERW pipe are all welded steel pipes and are classified based on the method of welding. For instance, LSAW pipe is welded longitudinally, and SSAW pipe is spiral-welded. ERW pipe is electric resistance welded, which results in a seam that runs parallel along the pipe body.

▇ ▍ERW Steel Pipe

High-frequency welded pipes are generally straight-slit, but straight-slit welded steel pipes are not necessarily high-frequency welded. The high-frequency straight-slit electric resistance welded steel pipe is formed by the skin effect and the proximity effect of the high-frequency current after the hot-rolled coil plate is formed by the molding machine, and the edge of the tube blank is heated and melted, and pressure welding is performed under the action of the pressing roller to realize the production. The high-frequency resistance welded steel pipe is different from the ordinary welded pipe welding process. The weld is made of the base material of the steel strip body, and the mechanical strength is better than that of the general welded pipe. The surface is smooth, high precision, low cost, and has low weld seam height, which is beneficial to the coating of 3PE anti-corrosion coating.

▇ ▍LSAW Steel Pipe

Longitudinal submerged arc welded is produced by using a single medium and thick plate as the raw material, pressing (rolling) the steel plate in a mold or forming machine into a tube blank, using double-sided submerged arc welding, and expanding the diameter. The steel plate feed amount can be automatically adjusted according to different steel grades, wall thicknesses, and plate widths. At the same time, the deformation compensation function effectively avoids the adverse effects of mold deformation on the forming and ensures the flatness of the full length of the steel plate during the pressing process. The feeding step is uniform during forming, ensuring the roundness of the tube blank and the flatness of the welding edge. The finished product has a wide range of specifications, and the weld has good toughness, plasticity, uniformity, and compactness. It has the advantages of large pipe diameter, pipe wall thickness, high-pressure resistance, low-temperature resistance, and strong corrosion resistance.

▇ ▍SSAW Steel Pipe

Spiral welded pipe(SSAW pipe, also called HSAW pipe). The pipe is formed by spiral submerged arc welding technology. Spiral welded pipes are formed using narrower plates or hot rolled coils, which lowers their production costs significantly. The welding line shape like a helix. The spiral welding process permits the production of large-diameter pipes suitable for transporting large volumes of oil and gas. Some SSAW pipes were historically limited to low-pressure applications.

Post time: Oct-16-2023