ASTM A53 is a carbon steel that can be used as structural steel or for low pressure piping.

ASTM A53 carbon steel pipe (ASME SA53) is a specification covering seamless and welded black and hot dip galvanized steel pipe from NPS 1/8″ to NPS 26.A 53 is designed for pressure and mechanical applications and is also available for general application.Steam,water, gas and air lines.

Pipe A53 is available in three types (F, E, S) and two grades (A, B).A53 Type F made by oven butt welding or continuous seam welding (Grade A only) A53 Type E by resistance welding (Classes A and B).

Class B A53 seamless tubing is our most extreme product under this specification. A53 tubing is usually dual certified compared to A106 B seamless tubing.

ASTM A53 seamless steel pipe is an American standard grade.A53-F corresponds to Chinese material Q235,A53-A corresponds to Chinese material No. 10,and A53-B corresponds to Chinese material No.20.

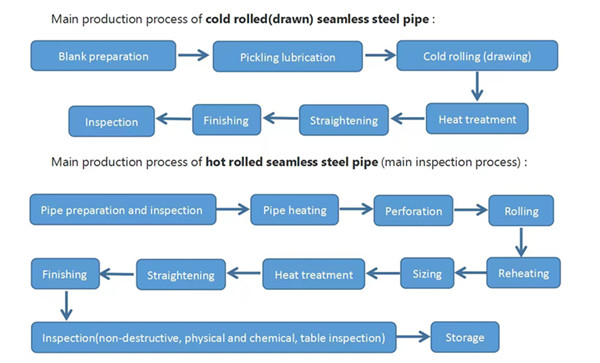

Production process Seamless steel pipes are divided into hot-rolled seamless pipes and cold-rolled seamless pipes according to the production process.

1. The production process of hot rolled seamless steel pipe: tube billet → heating → perforation → three-roll / cross rolling → pipe removal → sizing → cooling → straightening → hydraulic testing → marking → lever detection of seamless steel pipe. Effect. 2. Production process of cold drawn seamless steel pipe: tube billet → heating → perforation → blanking → annealing → pickling → oiling → multiple cold drawing → tube billet → heat treatment → straightening → hydraulic testing → marking → injection library.

Application 1. Construction: underground pipelines, underground water, hot water transportation. 2. Machining, bearing bushes, machine parts processing, etc. 3. Electrical: gas pipelines, hydroelectric pipelines 4. Anti-static pipes for wind power, etc.

Post time: Apr-12-2023