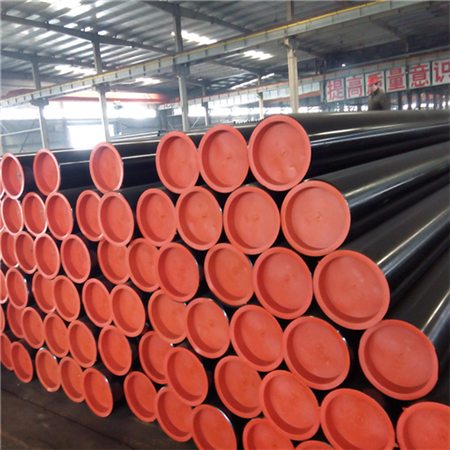

ERW steel pipes are made with low frequency or high frequency electrical resistance "resistance". They are round pipes welded from steel sheets with longitudinal seams. It is used to transport gas and liquid objects such as oil and natural gas, and can meet various requirements of high and low pressure. It currently occupies a key position in the field of transport pipelines in the world.

When welding ERW pipes, heat is released when current flows through the contact surfaces of the welding zone. It heats two edges of steel to the point where one edge can form a bond. In this case, under joint pressure, the edges of the pipe blank are melted and extruded together.Typically ERW pipes have a maximum outer diameter of 24 inches (609 mm), larger pipes are made using SAW.

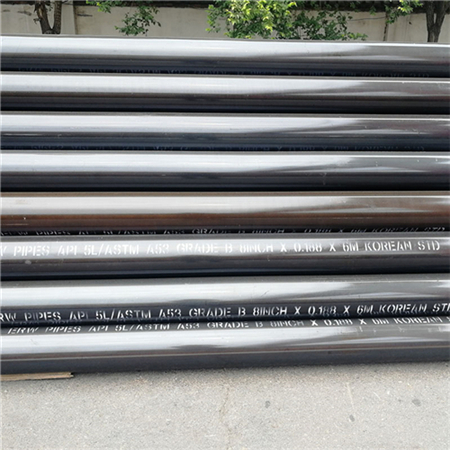

There are many pipes that can be made using the ERW method. Below we list the most common standards in plumbing.ERW ASTM A53 Grade A and B carbon steel pipes (and galvanized) ASTM A252 carbon steel pipes ASTM A500 pile pipes ASTM A134 and ASTM A135 structural pipes EN 10219 pipes S275,S355 pipes.ERW Stainless Steel Pipe ASTM A269 Standards & Specifications ASTM A270 Stainless Steel Pipe ASTM A312 Plumbing Pipe ASTM A790 Stainless Steel Pipe Ferritic/Austenitic/Duplex Stainless Steel Pipe.API ERW line pipe API 5L B to X70 PSL1 (PSL2 must be HFW process) API 5CT J55/K55,N80 casing and tubing.

Application and use of ERW steel pipe: ERW steel pipe is used for transporting gas and liquid objects such as oil and natural gas, and can meet low and high pressure requirements. In recent years,with the development of ERW technology, more and more ERW steel pipes are used in oil and gas fields,automotive industry, etc.

Post time: Apr-12-2023