Li-arc welding tse ka tlas'a metsi li loketse liphaephe, likepe tsa khatello le litanka, ho etsoa ha literene le lisebelisoa tse kholo tsa kaho, ka mokhoa o bonolo ka ho fetisisa oa monofilament, mohaho oa mohala o habeli, mohaho oa terata oa tandem le mefuta e mengata ea li-filament.

Welding ea arc e ka tlas'a metsi e ka thusa basebelisi lits'ebetsong tse ngata tsa welding.Ho tloha ho eketsa tlhahiso, ho ntlafatsa tikoloho ea mosebetsi, ho netefatsa boleng bo tsitsitseng le tse ling.Baetsi ba lisebelisoa tsa tšepe ba nahanang ka liphetoho tse etsoang ka tlas'a metsi arc welding ba ne ba lokela ho nahana hore ba ka fumana melemo e mengata ts'ebetsong ena.

Tsebo ea mantlha ea welding ea arc e ka tlas'a metsi

Ts'ebetso ea welding ea arc e ka tlas'a metsi ke tlhokahalo e loketseng lits'ebetso tse boima tsa indasteri joalo ka liphaephe, likepe tsa khatello le litanka, kaho ea literene, kaho e boima / ho cheka.E loketse liindasteri tse hlokang tlhahiso e phahameng, haholo-holo ha ho tluoa tabeng ea ho cheselletsa thepa e teteaneng haholo, ho na le melemo e mengata e ka fumanoang ts'ebetsong ea welding ea arc e ka tlas'a metsi.

Sekhahla sa eona se phahameng sa deposition le lebelo la ho tsamaea li ka ba le tšusumetso e kholo tlhahisong ea basebetsi, katleho le litšenyehelo tsa tlhahiso, e leng e 'ngoe ea melemo ea bohlokoa ea ts'ebetso ea ho tjheseletsa arc ka metsing.

Melemo e meng e kenyelletsa: Motsoako o motle oa lik'hemik'hale le thepa ea mochini oa weld, ponahalo e nyane ea arc le mosi o tlase oa welding, boiketlo bo ntlafalitsoeng ba tikoloho ea ho sebetsa, le sebopeho se setle sa weld le mohala oa menoana.

Submerged arc welding ke mokhoa oa ho fepa oa terata o sebelisang granular flux ho arola arc moeeng, joalo ka ha lebitso le bontša, arc e patoa ka phallo, e bolelang hore ha li-parameter li behiloe, arc ha e bonahale ka ho tsoa ha li-arc. lera la phallo.Mohala oa ho tjheseletsa o fepuwa nako le nako ke toche e tsamayang ho bapa le weld.

Ho futhumatsa ha Arc ho qhibilihisa karolo ea terata, karolo ea phallo le tšepe ea motheo, ho etsa letamo le qhibilihisitsoeng, le kopanyang ho etsa weld e koahetsoeng ka lera la tjheseletsa slag.Botenya ba thepa ea ho tjheseletsa ke 1/16 "-3/4", e ka ba 100% ho kenella ka tjheseletsa ka ho tjheseletsa e le 'ngoe, haeba botenya ba lebota bo sa lekanyetsoe, ho ka etsoa welding ea li-multi-pass,' me weld e ka etsoa ka mokhoa o nepahetseng. e khethiloe, 'me ho khethoa motsoako o nepahetseng oa ho tjheseletsa terata.

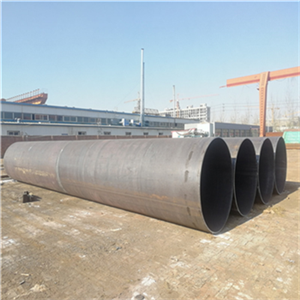

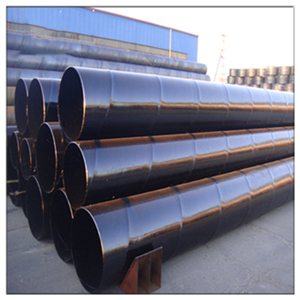

LSAW

ERW

SSAW

Khetho ea terata ea flux le welding

Ho khetha mohala o nepahetseng le terata bakeng sa ts'ebetso e itseng e ka tlas'a metsi ea arc welding ke ea bohlokoa ho fihlela litholoana tse ntle ka ho fetisisa ka ts'ebetso.Le ha lits'ebetso tsa welding tsa arc tse ka tlas'a metsi li sebetsa hantle, tlhahiso le katleho li ka eketsoa ho latela terata ea welding le flux e sebelisitsoeng.

Phallo ha e sireletse letamo la weld feela, empa hape e kenya letsoho ntlafatsong ea thepa ea mochini le tlhahiso ea weld.Ho hlophisoa ha li-fluxes ho na le tšusumetso e kholo linthong tsena, ho ama bokhoni ba hona joale ba ho jara le ho lokolloa ha slag.

Bokhoni ba hona joale ba ho jara bo bolela hore ho ka fumanoa ts'ebetso e phahameng ka ho fetesisa ea deposition le profil ea boleng bo holimo ea weld.

Ho lokolloa ha Slag ho tsoa ho phallo e itseng ho ama khetho ea phallo hobane li-flux tse ling li loketse meralo e itseng ea solder ho feta tse ling.

Likhetho tsa khetho ea Flux bakeng sa solder e ka tlas'a metsi e kenyelletsa mefuta e sebetsang le e sa nke lehlakore ea li-welds.Phapang ea mantlha ke hore phallo e sebetsang e fetola k'hemistri ea weld, athe ho se nke lehlakore ha ho joalo.

Li-fluxes tse sebetsang li khetholloa ka ho kenyelletsa silicon le manganese.Lintho tsena li thusa ho boloka matla a tsitsitseng a weld ka mocheso o phahameng oa mocheso, ho thusa ho boloka weld e boreleli le e boreleli ka lebelo le phahameng la maeto le ho fana ka tokollo e ntle ea slag.Ka kakaretso, li-fluxes tse sebetsang li ka thusa ho fokotsa kotsi ea boleng bo tlaase ba solder, hammoho le ho hloekisa ka mor'a ho cheselletsa le ho sebetsa hape.Leha ho le joalo, hopola hore li-fluxes tse sebetsang hangata li loketse hantle bakeng sa solder e le 'ngoe kapa habeli.

Li-fluxes tse sa nkeng lehlakore li molemo bakeng sa li-solders tse kholo tsa multipass hobane li thusa ho qoba ho thehoa ha li-welds tse brittle, tse nang le crack.

Ho na le mefuta e mengata ea likhetho tsa terata ea welding mabapi le welding ea arc e ka tlas'a metsi, e 'ngoe le e' ngoe e na le melemo le mathata.Lithapo tse ling li entsoe bakeng sa ho cheselletsa mocheso o phahameng, ha tse ling li etselitsoe ho ba le li-alloys tse thusang ho hloekisa.

Hlokomela hore thepa ea lik'hemik'hale le tšebelisano ea mocheso oa mocheso oa terata ea welding e ama thepa ea mochine oa weld.Tlhahiso e ka boela ea eketseha haholo ka khetho ea tšepe ea filler.

Mohlala, ho sebelisa terata ea mantlha ea tšepe e nang le ts'ebetso ea welding ea arc e ka tlas'a metsi ho ka eketsa katleho ea deposition ka 15% ho isa ho 30% ha e bapisoa le ho sebelisa terata e tiileng, ha e ntse e fana ka profil e pharaletseng le e sa tebang ea ho kenella.

Ka lebaka la lebelo la eona le phahameng la ho tsamaea, lithapo tsa mantlha tsa tšepe li boetse li fokotsa ho kenya mocheso ho fokotsa kotsi ea ho senyeha ha tjheseletsa le ho felloa ke matla.

Har'a litšepe tsohle, litšepe tsa austenitic li na le ntlha e tlase ea tlhahiso.Ka hona, mabapi le thepa ea mechine, tšepe ea austenitic e sa hloekang hase eona ntho e molemo ka ho fetisisa bakeng sa stem ea valve, hobane ho tiisa matla a itseng, bophara ba sekhahla sa valve se tla eketseha.Ntlha ea lihlahisoa e ke ke ea eketseha ka phekolo ea mocheso, empa e ka eketsoa ka ho theha serame.

Re stockist ea carbon le phala ea tšepe e se nang seamless, re amohela lipotso leha e le life, re tla fana ka tsona ka lekhetlo la pele!

Nako ea poso: Jan-30-2023